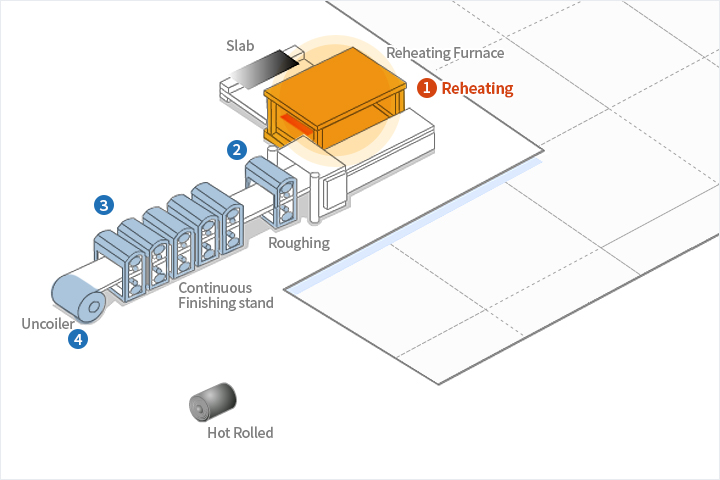

Introduction to Hot Rolling

Hot rolling is a rolling process that is carried out above the recrystallization temperature of metals. At this temperature, metals exhibit high plasticity and low deformation resistance, which favors the rolling into various shapes and sizes of steel products. Hot rolling significantly improves the processing properties of metals and alloys, reduces energy consumption during metal deformation, and lowers production costs.

Definition of Hot Rolling

Hot rolling, in contrast to cold rolling, which is performed below the recrystallization temperature, involves rolling metals above their recrystallization temperature. Specifically, a steel billet is heated to a certain temperature in a heating furnace, then undergoes several rolling passes, followed by edge trimming and straightening to become steel plates or other shapes of products.

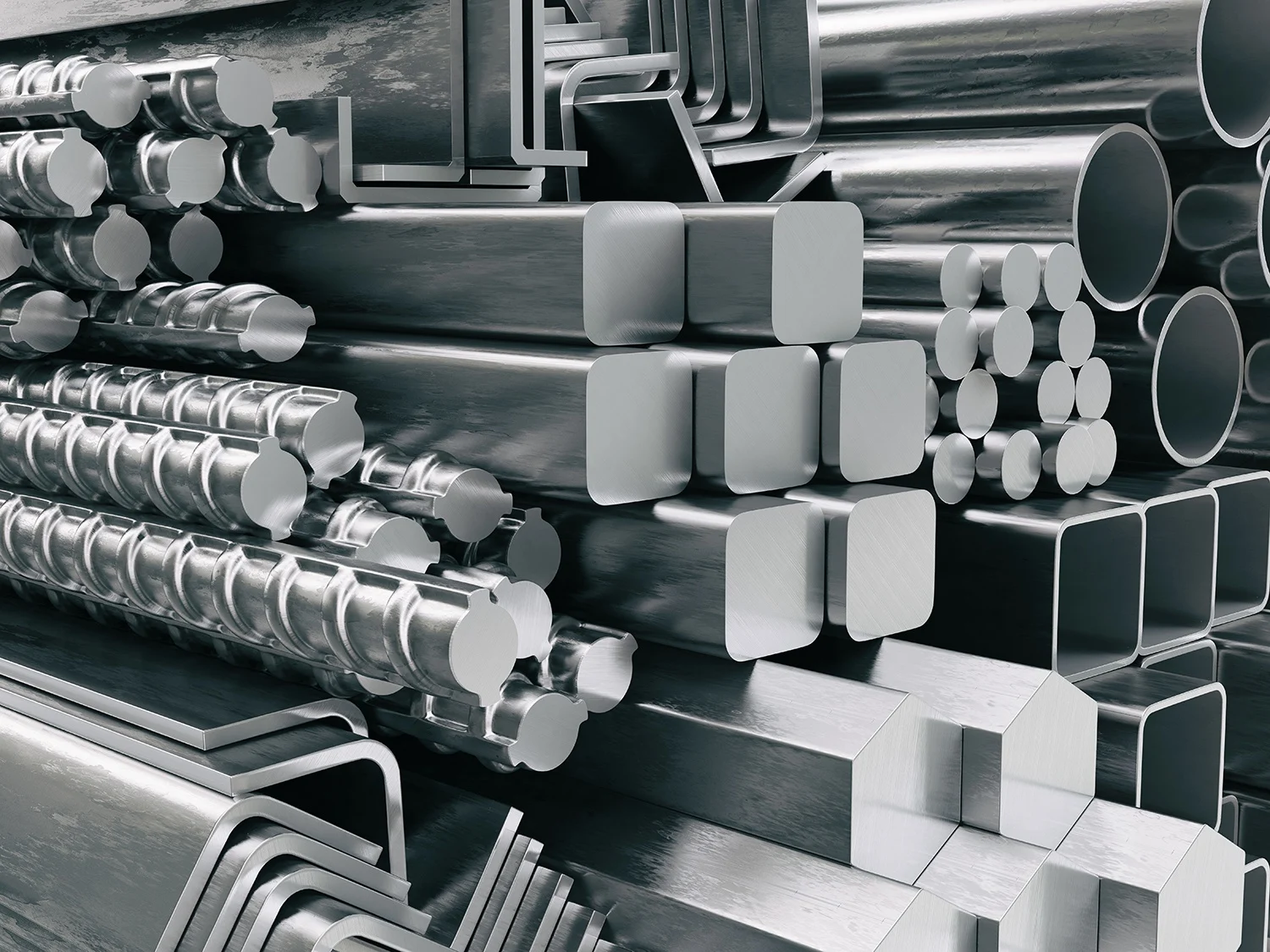

Applications of Hot Rolling

Hot rolling has extensive applications in metal material processing, primarily for producing plate and strip, bars, sections, and thin sheets. These products are widely used in the construction of structural components, automotive parts, pipelines, ships, bridges, and other large-scale engineering projects. They are also used in the manufacture of mechanical parts, bearings, bolts, nuts, and other industrial products. Additionally, hot rolling is employed in the production of stainless steel, aluminum, and alloy materials to meet the requirements of different industries for material properties and dimensions.

Classification of Hot Rolling

Hot rolling can be classified in different ways based on various criteria. Here are two common classification methods:

- Classification by Product Type:

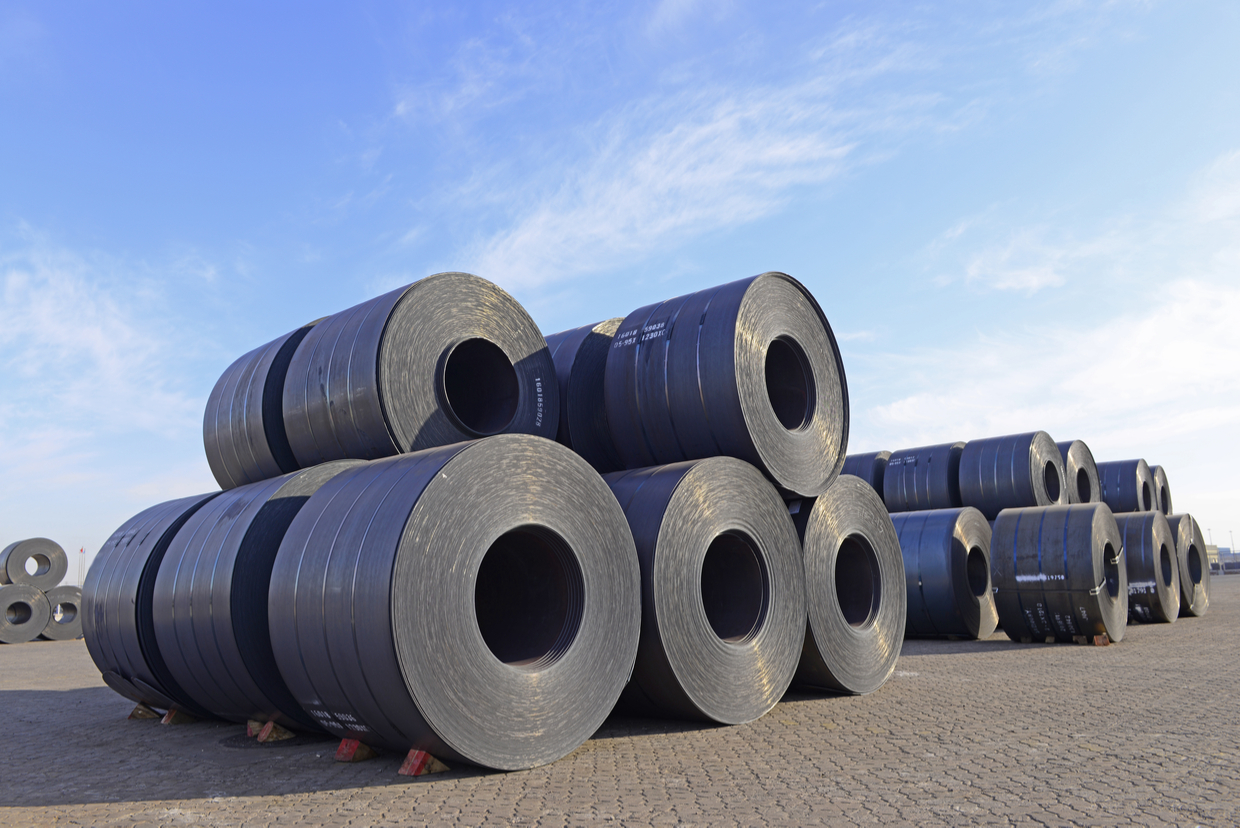

- Hot-rolled plate and strip: Including hot-rolled steel plates and hot-rolled steel strips.

- Hot-rolled bars: Refers to round bars with a diameter above 6mm.

- Hot-rolled sections: Such as angle steel, channel steel, I-beams, and H-beams.

- Hot-rolled thin sheets: Sheets with a thickness of less than 3mm.

- Classification by Rolling Method:

- Longitudinal rolling: Rolling along the length direction of the steel material.

- Transverse rolling: Rolling along the width direction of the steel material.

Common Steel Grades for Hot Rolling

There are numerous steel grades for hot-rolled steel, and here are some common domestic and international standard grades:

- Domestic Standard Grades:

- Q235: A commonly used carbon structural steel with good plasticity and weldability.

- Q345: A low-alloy high-strength structural steel with high strength and toughness.

- Q550: A high-strength structural steel with excellent comprehensive mechanical properties.

- International Standard Grades:

- ASTM A36: A commonly used carbon structural steel widely applied in construction and bridge projects.

- ASTM A572: A high-strength low-alloy structural steel with excellent impact resistance and toughness.

- SS400: A Japanese standard carbon structural steel with good plasticity and weldability.

Hot rolling, as an important metal material processing technique, has widespread applications in various fields.