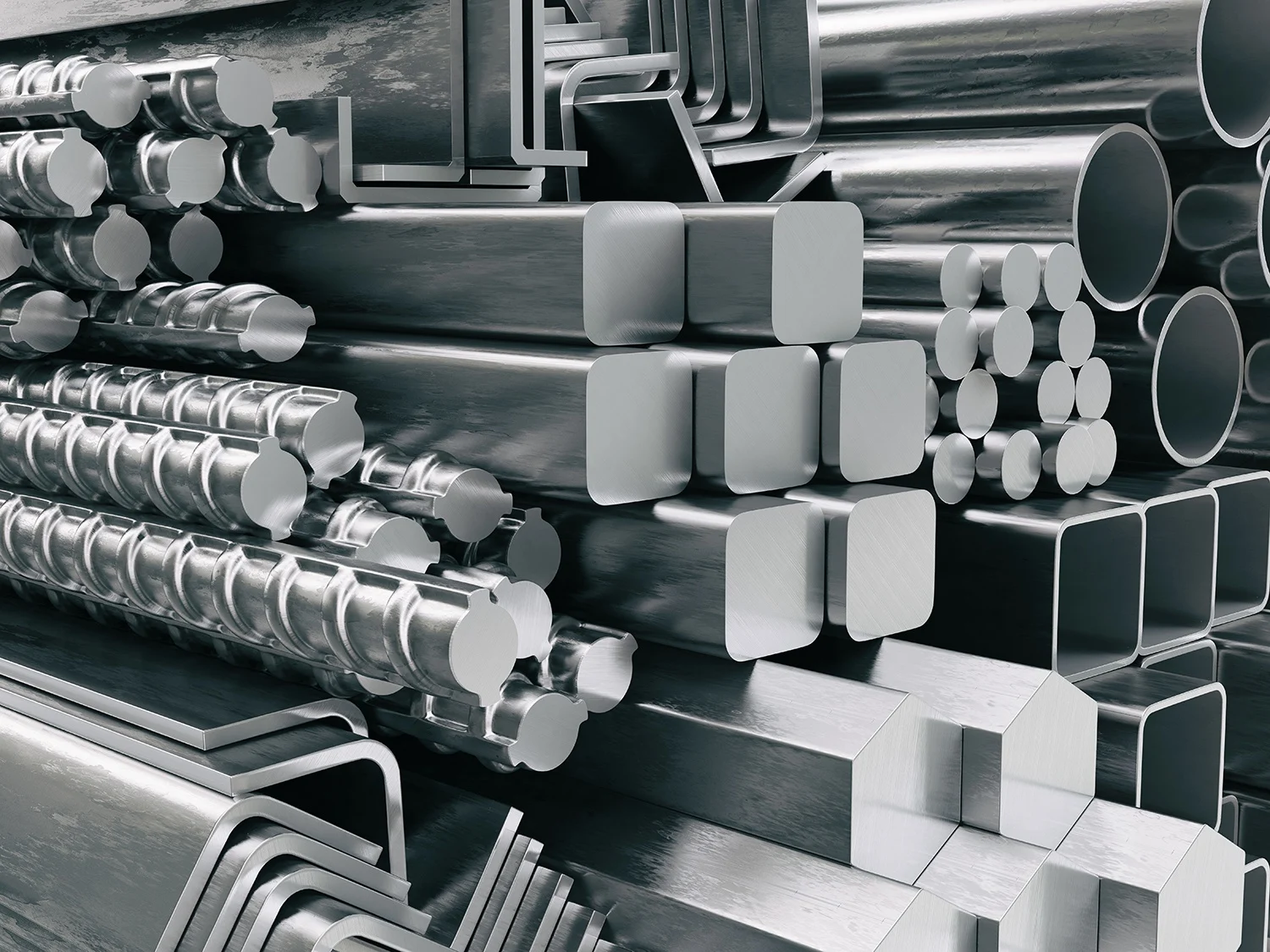

Overview of Special Steel

Special steel, also known as special-purpose steel or specialty steel, refers to steel products with unique physical, chemical, or functional properties due to their specific chemical composition, structure, and production processes. As a branch of the traditional steel industry, special steel differs significantly from general steel in terms of its usage. Special steel is characterized by its high strength and toughness, physical and chemical properties, biocompatibility, processability, high purity, high uniformity, ultra-fine structure, and high precision.

Definition

Special steel refers to steel with specific chemical compositions (alloying), produced through unique processes, possessing unique microstructures and properties, and meeting specific requirements.

Applications

Special steel is primarily used in the following industries:

- Automotive: For manufacturing engine, transmission, chassis, and other critical components.

- Machinery Manufacturing: For manufacturing high-precision, high-load, and high-wear-resistant machine parts.

- Petrochemical: For manufacturing refining, chemical processing equipment, and more.

- Aerospace and Military: For manufacturing key components of aircraft, missiles, satellites, and others.

Classification

Special steel can be classified in several ways, including the following:

- By Application:

- Tool steel: Used for manufacturing various tools, such as cutting tools, measuring tools, and more.

- Structural steel: Primarily used in construction, machinery, automobiles, aviation, and other industries.

- Special-purpose steel: Including stainless steel, high-speed steel, bearing steel, spring steel, and other steel types with specific properties.

- By Technological Content and Product Grade:

- High-end products: Represented by stainless steel, tool steel, mold steel, and high-speed steel.

- Mid-range products: Represented by alloy steel (excluding stainless steel, tool steel, mold steel, and high-speed steel).

- Low-end products: Represented by high-quality carbon structural steel (carbon steel).

- By Carbon Content:

- Low-carbon steel: Steel with a carbon content of less than 0.25%.

- Medium-carbon steel: Steel with a carbon content ranging from 0.25% to 0.65%.

- High-carbon steel: Steel with a carbon content exceeding 0.65%.

Common Steel Grades

Special steel has numerous commonly used steel grades, including the following examples:

- Stainless Steel: Such as 304, 316, etc., with excellent corrosion resistance.

- High-speed Steel: Such as W18Cr4V, W6Mo5Cr4V2, etc., characterized by high hardness, wear resistance, and red hardness.

- Bearing Steel: Such as GCr15, GCr15SiMn, etc., with high and uniform hardness, wear resistance, and contact fatigue performance.

- Mold Steel: Such as H13, P20, etc., with excellent wear resistance, toughness, and thermal stability.

The choice of these steel grades depends on specific application scenarios and requirements. For instance, 06Cr12Ni25Mo3Cu3Si2N stainless steel pipes can be selected for the manufacture of sulfuric acid-resistant pipelines, pumps, valves, towers, containers, and other equipment and components. Special steel grades like 310S with excellent high-temperature resistance can be used for the manufacture of high-temperature equipment.