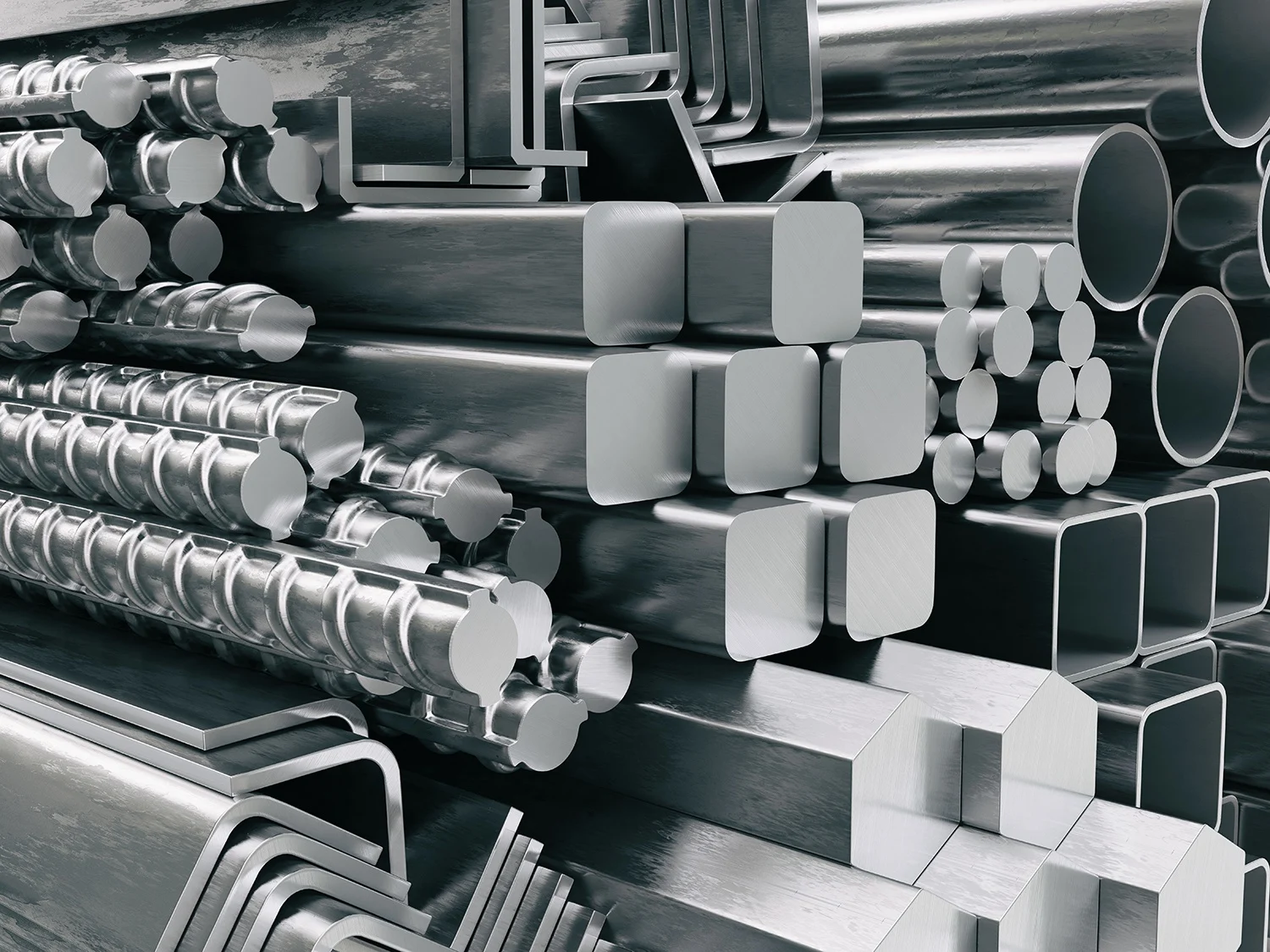

I. General Introduction of Steel Pipes

Steel pipes are metallic materials with a hollow cross-section made from steel, where the length is significantly greater than the diameter or perimeter. Steel pipes are not only used for transporting fluids and powdered solids, exchanging heat energy, manufacturing mechanical parts and containers, but they are also an economical steel material. Due to their excellent physical and chemical properties, steel pipes have widespread applications in multiple industries.

II. Definition

Steel pipes refer to metallic materials made from steel with a closed hollow cross-section, where the length is significantly greater than the outer diameter (or side length). They are suitable for transporting fluid media such as water, oil, and gas.

III. Applications

- Pipeline Transportation: Steel pipes are widely used for transporting fluid media such as water, oil, and gas.

- Engineering Structures: They are used in manufacturing structural grids, pillars, and mechanical supports for buildings, which can reduce weight and save 20-40% of metal, while enabling factory-based and mechanized construction.

- Thermal Equipment: Steel pipes are utilized in various pipes and containers in thermal equipment.

- Petrochemical Industry: In the petrochemical industry, steel pipes are used to make reactors, separators, pipelines, etc.

- Machinery Manufacturing: Steel pipes are also an important material in the machinery manufacturing industry, used for making various mechanical parts and structural components.

- Geological Drilling: In the field of geological drilling, steel pipes are used as drill rods and casings.

- High-Pressure Equipment: Steel pipes are also used in manufacturing high-pressure equipment, such as high-pressure boiler tubes.

IV. Classification

- Classification by Cross-Section Shape:

- Round steel pipe

- Square steel pipe

- Rectangular steel pipe

- Irregular-shaped steel pipe

- Classification by Material:

- Carbon structural steel pipe

- Low-alloy structural steel pipe

- Alloy steel pipe

- Composite steel pipe

- Classification by Production Process:

- Seamless steel pipe: Including hot-rolled seamless pipe, cold-drawn pipe, precision steel pipe, etc.

- Welded steel pipe: Including straight seam welded steel pipe and spiral welded steel pipe.

V. Common Steel Grade Brands

There are numerous steel grades for steel pipes, and the following are some commonly used alloy steel pipe and pipe fitting materials:

- Monel Alloy: Monel 400, Monel K500, etc.

- Incoloy Alloy: Incoloy 800, Incoloy 825, etc.

- Inconel Alloy: Inconel 600, Inconel 625, etc.

- Hastelloy Alloy: Hastelloy C-276, Hastelloy B-2, etc.

- High-temperature Alloy: GH3030, GH4169, etc.

Alloy steel pipes are widely used in specific industrial fields due to their unique chemical composition and properties.